- All

- Product Management

- News

- Introduction

- Corporate Outlets

- FAQ

- Corporate Video

- Corporate Brochure

Contact Us

Headquarter Address: Baihao Industrial Zone, Houjie Town, Dongguan City, Guangdong Province

Tel:+86 769-85923778 85923738

85878200

Fax:+86769-85924507

Website:http://www.dg-xinghe.com

E-mail:cds@dg-xinghe.com

Magnetic powder clutch

- Product Description

-

PB and PC type magnetic powder brakes consist of an active rotor (input shaft), a passive rotor (output shaft), and a magnetic yoke containing an excitation coil. These three parts are assembled concentrically to form a relatively rotating unit. High-permeability alloy magnetic powder fills the annular gap between the active and passive rotors.

When no current flows through the excitation coil, the magnetic powder in the working chamber is loose. Under the action of the centrifugal force generated by the active rotor, the magnetic powder is evenly thrown onto the inner wall of the active rotor. There is little interaction between the active and passive rotors; the magnetic powder clutch is in a separated state, and no torque is transmitted.

The PC type magnetic powder brake works on the same principle as the magnetic powder clutch. Fixing the passive rotor of the magnetic powder clutch forms a magnetic powder brake.

Characteristics

1. Linear relationship between excitation current and torque

2. Stable slip torque

3. Prevents heat generation due to slippage

Application Range

Due to the above characteristics of PB and PC type magnetic powder brakes, they are now widely used in the control of winding and unwinding tension in papermaking, printing, plastics, rubber, textile, printing and dyeing, wire and cable, metallurgy, and other related industries.

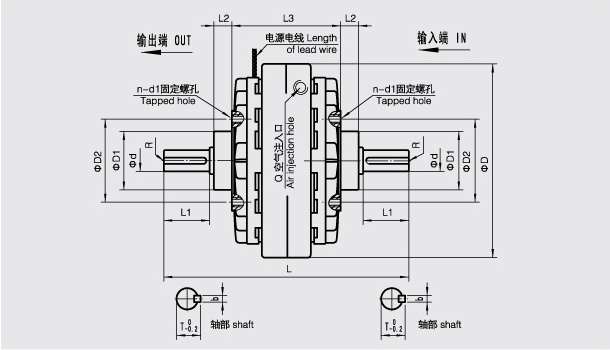

and dyeing, wire and cable, metallurgy, and other related roll processing industries for controlling winding and unwinding tension. ModelRated Torque (N•m)Current (A) 75℃Permissible Speed (r/min)Flywheel Distance J (kg cm 2)Slippage Power (W)Airflow (m 3 /min)Weight (Kg)Input ShaftOutput ShaftSelf-coolingAir-coolingPC-0.06BN0.60.4618006.10×10 -56.60×10 -620380.11.8PC-0.3BN30.5318003.00×10 -48.00×10 -550800.13.3PC-0.6BN60.8118006.00×10 -41.83×10 -4701300.14PC-1.2BN120.9418001.34×10 -34.90×10 -41502500.25.5PC-2.5BN251.2418003.80×10 -31.49×10 -32303800.410PC-5BN502.1518009.50×10 -34.80×10 -33607000.616PC-10BN1002.4018003.50×10 -32.50×10 -260011001.137PC-20BN2002.7018009.15×10 -26.89×10 -286019001.659PC-40BN4003.5018002.40×10 -12.20×10 -1130028002.0108ModelDimensionsShaft Connection DimensionsMouth Support DimensionsAir HoleDLd(h7)b(p7)TL1RX DepthD1(g7)D2L2L3n-d1x DepthPC-0.06BN88132839.122---335515506-M5×101/8PC-0.3BN12015410411.522M3×6426414706-M5×101/8PC-0.6BN13416412413.526M4×8426414726-M5×101/8PC-1.2BN1521921551729M4×8426415946-M6×101/8PC-2.5BN1822302052243M5×105578171026-M6×101/8PC-5BN2192942572855M6×1274100301126-M6×101/4PC-10BN2783603073365M10×20100140281606-M10×153/8PC-20BN327408351038.569M10×20110150301906-M10×153/8PC-40BN395500451248.592M10×20130200352216-M12×203/8

ModelRated Torque (N•m)Current (A) 75℃Permissible Speed (r/min)Flywheel Distance J (kg cm 2)Slippage Power (W)Airflow (m 3 /min)Weight (Kg)Input ShaftOutput ShaftSelf-coolingAir-coolingPC-0.06BN0.60.4618006.10×10 -56.60×10 -620380.11.8PC-0.3BN30.5318003.00×10 -48.00×10 -550800.13.3PC-0.6BN60.8118006.00×10 -41.83×10 -4701300.14PC-1.2BN120.9418001.34×10 -34.90×10 -41502500.25.5PC-2.5BN251.2418003.80×10 -31.49×10 -32303800.410PC-5BN502.1518009.50×10 -34.80×10 -33607000.616PC-10BN1002.4018003.50×10 -32.50×10 -260011001.137PC-20BN2002.7018009.15×10 -26.89×10 -286019001.659PC-40BN4003.5018002.40×10 -12.20×10 -1130028002.0108ModelDimensionsShaft Connection DimensionsMouth Support DimensionsAir HoleDLd(h7)b(p7)TL1RX DepthD1(g7)D2L2L3n-d1x DepthPC-0.06BN88132839.122---335515506-M5×101/8PC-0.3BN12015410411.522M3×6426414706-M5×101/8PC-0.6BN13416412413.526M4×8426414726-M5×101/8PC-1.2BN1521921551729M4×8426415946-M6×101/8PC-2.5BN1822302052243M5×105578171026-M6×101/8PC-5BN2192942572855M6×1274100301126-M6×101/4PC-10BN2783603073365M10×20100140281606-M10×153/8PC-20BN327408351038.569M10×20110150301906-M10×153/8PC-40BN395500451248.592M10×20130200352216-M12×203/8

Keyword:

Product Inquiry

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products